Key components of the injection molding machine

Acid and corrosion resistant, wear-resistant, high-strength alloy materials and their application technology.

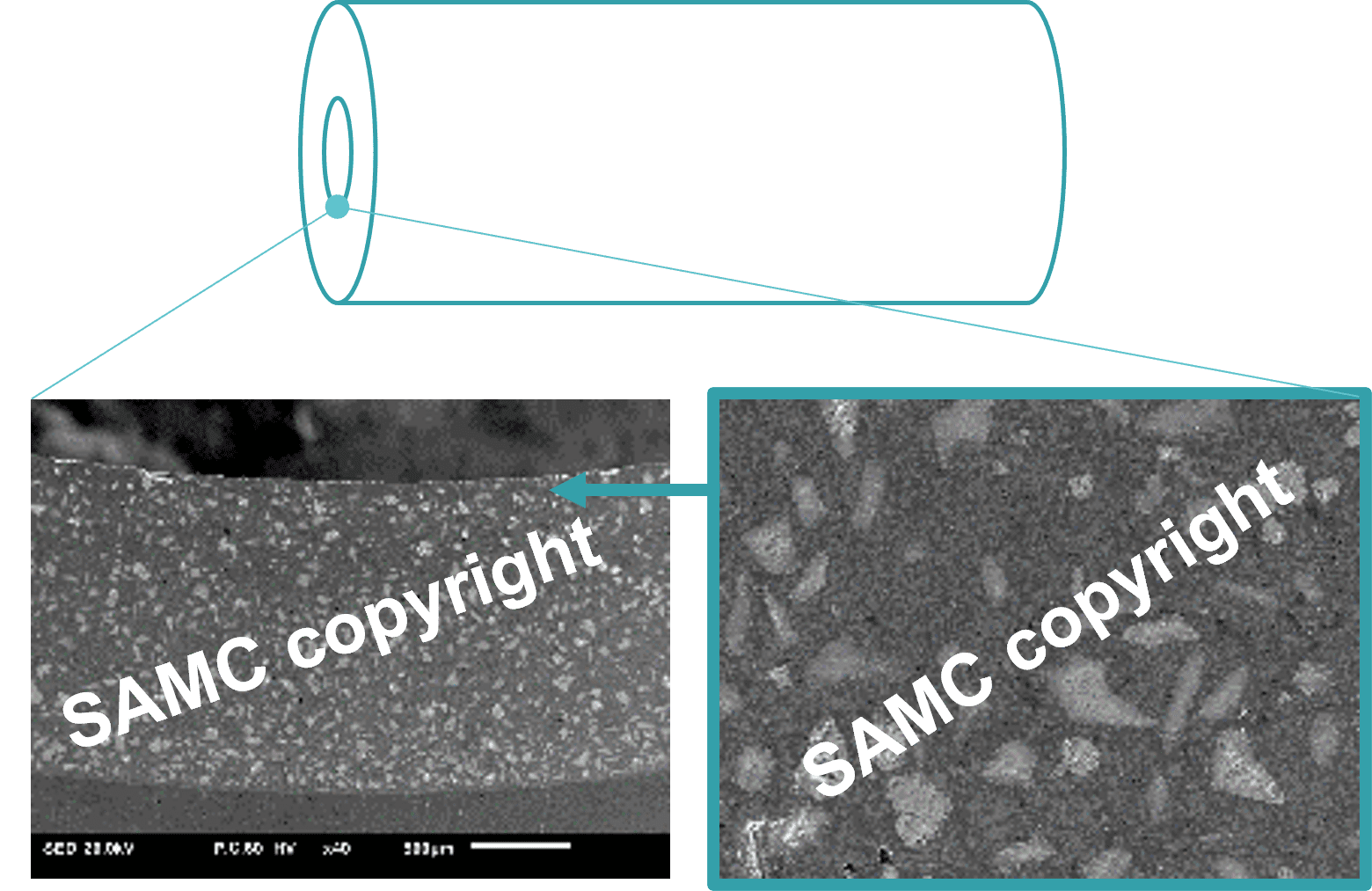

SAMC is a type of surface-enhanced product made of ultra-hard alloy tubes. It is created using a combination of inner-layer rotational electroplating or powder metallurgy processes. The resulting wear-resistant and corrosion-resistant coating is 1-2mm thick and has a strength of HRC60. This coating reduces material costs and machine downtime, avoids the need to reconfigure production parameters, and effectively enhances production efficiency.

A uniform alloy layer

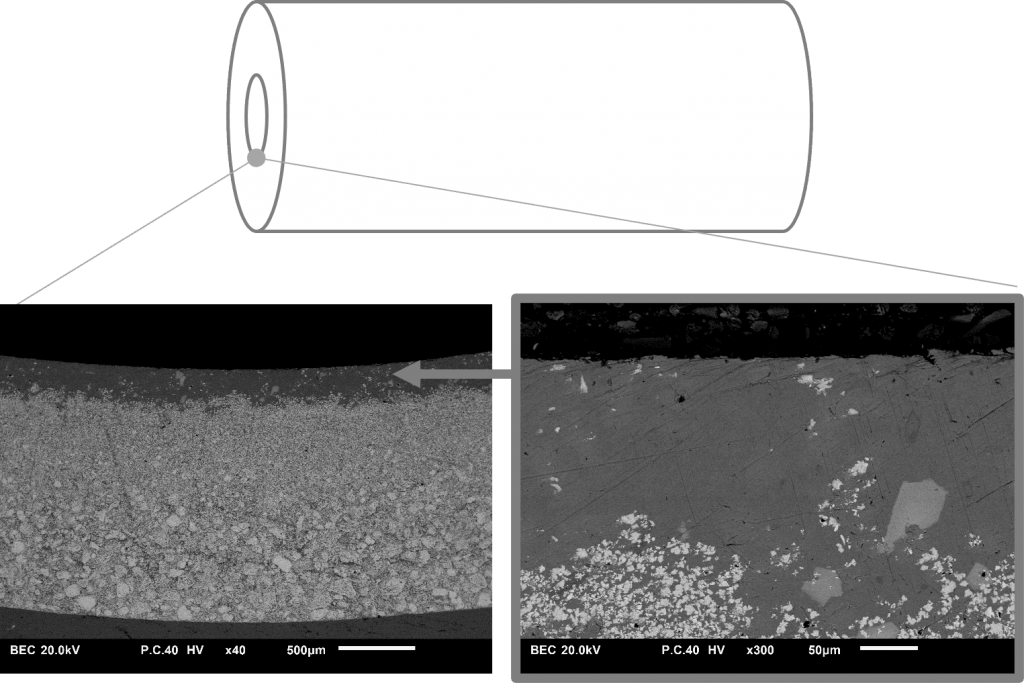

The inner wall of the alloy layer is the first line of defense against injected materials and must withstand extreme environments and the abrasion of fiberglass. Compared to other manufacturers, SAMC has a more uniform distribution of strengthening materials on the surface, providing a considerable degree of surface abrasion resistance. The distribution of strengthening materials on the surface can better demonstrate the wear resistance of the alloy layer compared to the average hardness value.

SAMC

A uniform alloy layer provides good wear resistance on the surface.

Competitor 1

The lack of strengthening materials on the surface results in poorer actual wear resistance during use.

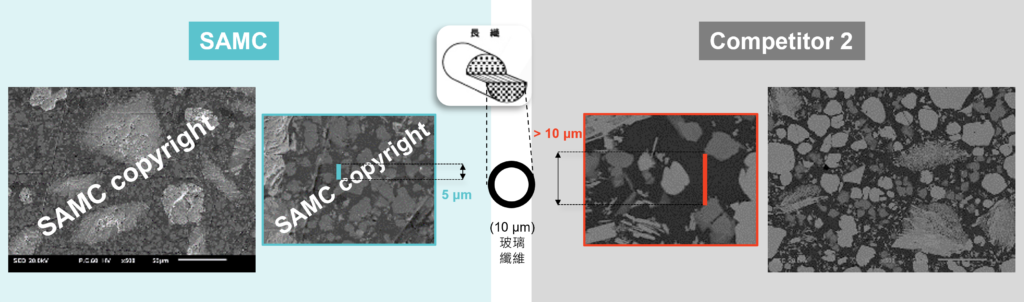

More finely dispersed strengthening materials.

Fine distributed reinforcement material provides excellent hardness to the alloy layer. The average gap between particles of the reinforcement material is less than 5 μm, which can effectively block the wear of the softer matrix alloy by glass fibers (diameter 10 μm), thereby improving the overall service life.

The average gap between the small gray particles < 5 μm

The matrix alloy is not easily worn down, resulting in an extended lifespan for the alloy layer.

The average gap between the small gray particles < 10 μm

Glass fibers are more prone to wear and can hollow out the matrix alloy, causing the reinforcement material to peel off and reducing the service life.

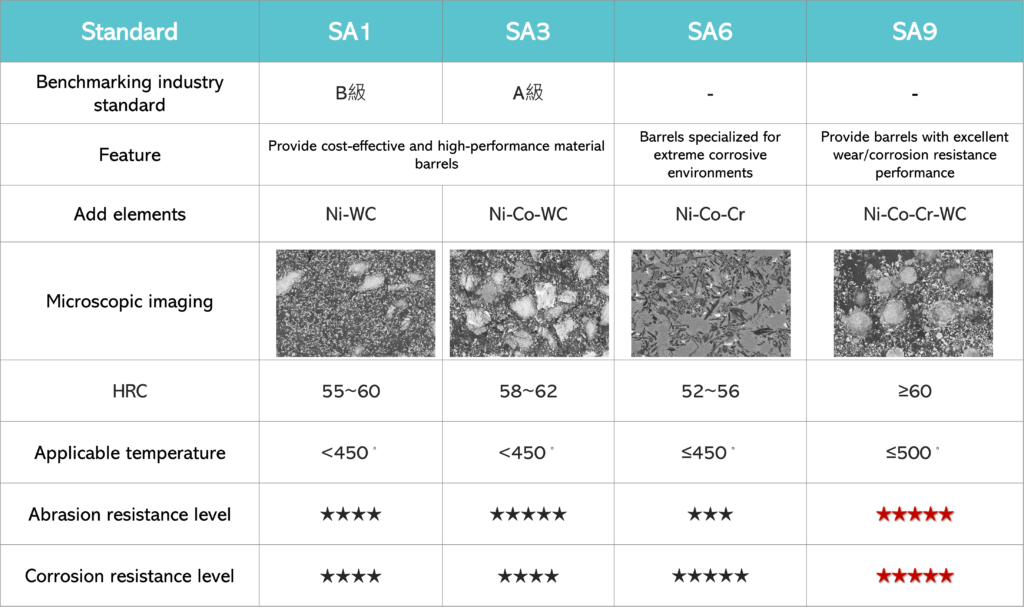

Specification sheet